February 22, 2019

Case Studies, Environmental

The Swiss Army Knife of Wastewater Treatment

An industrial wastewater treatment plant in beautiful Abony, in Hungary, had a problem, well several problems, with their plant.

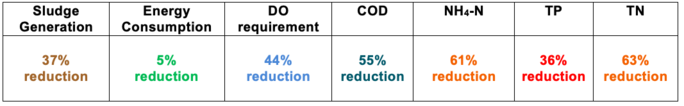

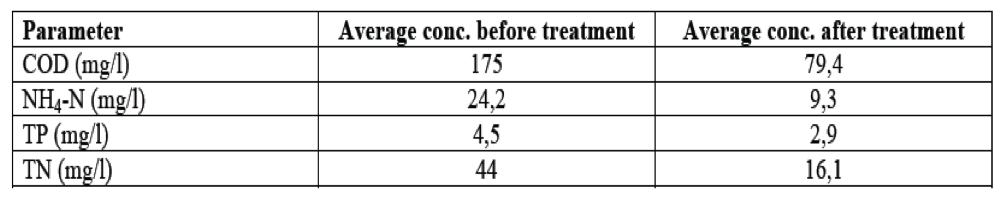

The plant had sludge build-up, high levels of COD, TP, NH4-N, and TN, and was consuming a lot of power.

Challenges

Our experts studied the data from the plant, discussed the challenges with the team, and established the following goals

- improve the activated sludge’s treatment capacity

- improve sludge resistance against shock loads and reduce excess sludge formation

- reduce the oscillation and overall concentration of the effluent parameters (NH4-N, TN, COD, BOD

Treatment

Our experts reviewed the data and goals and recommended Bioclean. Bioclean is our custom-made superhero.

A heterogenous consortium of multiple strains ensuring it adapts well to capricious conditions in an industrial wastewater treatment plant, Bioclean is specially designed to perform degradation of harmful organic pollutants in wastewater treatment plants.

The microbes in Bioclean can sustain high TDS (Total Dissolved Solids) levels under variable shock loads and reduce high COD/BOD levels.

Bioclean is also extremely energy efficient, resulting in energy savings and reduced capex/opex costs at the plant.

We initially applied Bioclean in a shock dose of 10 kg/day in the first week and subsequently reduced to 1 kg/day in 11 weeks and have maintained this dosage since.

Results

The average quantity of the dewatered sludge was 238 m3/month before the biotechnological optimisation.

This quantity considerably decreased during the treatment, coming down to an average amount of 149 m3/month.

A primary clarifier reduces the levels of suspended solids through primary wastewater treatment, and flocculants are generally added to cluster the suspended solids together so they can be separated easily.

However, this plant has no primary clarifier, yet our Bioclean was able to do the job efficiently and the degradation of organic particles added to the decrease in the quantity of excess sludge.

The most important goal was to reduce excess sludge which was addressed efficiently by degradation.

An additional benefit was a drastic reduction in transport costs.

The oxygen in the treatment system was also utilized productively, thereby decreasing dissolved oxygen levels from 1.8 mg/L to 1.0 mg/L and reducing energy consumption levels efficiently by 5%.

The average quantity of the dewatered sludge was 238 m3/month before the biotechnological optimisation.

This quantity considerably decreased during the treatment, so since the startup phase, the average amount has been 149 m3/month.

The quality of the effluent water also improved as a result of efficient organic breakdown and stable nitrification, and the fluctuation of the parameters has been moderated.

The operation of the secondary clarifier was stabilised by the improvement of the floc structure, which also reduced the suspended solids content of the effluent water.

All in all, an excellent result all round performance, as we witness with Bioclean every single time.

All in all, an excellent result all round performance, as we witness with Bioclean every single time.

Our clients were equally appreciative of the results we delivered with Bioclean, which helped them resolve all issues and reduce operational costs.

Use the button below to learn more about Bioclean and our microbial solutions for industrial wastewater treatment.

Also Read –

- Green Wastewater Treatment That Treats all Colours Equally

- https://organicabiotech.com/fundamentals-of-biological-wastewater-treatment/

- https://organicabiotech.com/why-innovative-wastewater-treatment-solutions-are-urgently-needed-in-india/

- https://organicabiotech.com/mitigating-antibiotic-resistance-efficient-wastewater-treatment/

- https://organicabiotech.com/how-microbes-improve-aerobic-wastewater-treatment-efficiency/

- https://organicabiotech.com/what-are-the-three-stages-of-wastewater-treatment/